5 tips for optimising energy consumption in building winter operation

Practical measures to reduce energy use during the heating season – heating, ventilation and BMS

Winter is peak season for energy consumption in offices, retail buildings, schools, institutions and other public buildings. As heating demand increases, even small operational or control issues can quickly become costly – both in terms of energy bills and occupant comfort.

High energy consumption during winter is rarely caused by a single factor. More often, it is the result of several combined issues: systems that do not work together, settings that have not been adjusted over time, and limited insight into how the building actually operates on a day-to-day basis.

Below, our energy consultant shares five operational tips based on experience from managing large building portfolios.

Key

Takeaways

- The greatest energy savings in winter operation are often found in control and operation – not in new installations.

- Ventilation is one of the largest energy consumers in winter if it is not controlled according to actual demand.

- Incorrect heating curves often result in overheating and unnecessarily high heat consumption.

- Poorly configured BMS systems can lead to significant energy waste without continuous monitoring, for example via an EMS.

- Access to energy data makes it possible to detect faults early and optimise operation across multiple buildings.

Tip 1

Reduce energy consumption by prioritising heating systems over ventilation

A common winter issue in larger buildings is that the ventilation system ends up providing a significant share of the heating. This rarely happens intentionally, but is often caused by a lack of coordination between heating and ventilation systems.

In a well-operated building, space heating should primarily be delivered by fixed heating sources such as radiators, fan heaters and underfloor heating. The heating coil in the ventilation system should only supplement when needed. When ventilation becomes the primary heat source, it often leads to both comfort issues and unnecessarily high energy consumption.

Typical consequences include:

- draughts and uneven indoor temperatures

- higher heat consumption than necessary

- dissatisfaction among building occupants

Heating via ventilation is rarely energy-efficient and should be considered a temporary solution rather than normal operation.

Tip 2

Control ventilation based on actual demand using CO₂ data

Many ventilation systems in larger buildings are equipped with CO₂ sensors, but in practice these are often used only to document air quality – not as an active control tool.

CO₂ levels provide a precise indication of when ventilation is actually required and how much air the building needs. Despite this, many systems still operate on fixed schedules or at high capacity “just to be safe”, particularly during winter.

This often results in:

- heated air being exhausted directly outside

- unnecessary increases in heating demand

- increased wear on ventilation systems

When ventilation is controlled according to actual demand, energy consumption can be reduced without compromising indoor climate quality.

Tip 3

Optimise heat consumption by correctly adjusting heating curves

Weather compensation is an effective tool for energy-efficient heating – but only if the heating curve is correctly set. In many buildings, the heating curve still reflects the building’s historical condition rather than its current insulation level and energy demand.

We often see buildings where upgrades such as new windows, additional insulation or roof renovations have been completed without adjusting the heating curve accordingly. The result is overheating, particularly during mild winter periods, and unnecessary energy consumption.

The placement of outdoor temperature sensors is especially important:

- incorrect placement can result in misleading temperature readings

- solar exposure can unnecessarily increase supply temperatures

- small deviations can lead to significant additional consumption over an entire winter

Outdoor temperature sensors should typically be installed on a north- or north-west-facing façade, in the shade and without direct sunlight, to ensure accurate temperature measurements.

Heating curves should be continuously adapted to the building’s actual needs.

Tip 4

Avoid unnecessary energy waste through continuous BMS follow-up

The Building Management System (BMS) controls the building’s technical installations, but it does not automatically detect inefficient operation. Many issues develop gradually or occur due to small changes in system settings.

During winter operation, common issues include:

- ventilation or cooling running at night

- systems starting long before the building is occupied

- overlap between heating and cooling in the same space

- systems unintentionally running continuously after service or faults

Without continuous follow-up, these issues can persist for weeks or months. Over an entire heating season, even small deviations can result in significant additional costs.

Tip 5

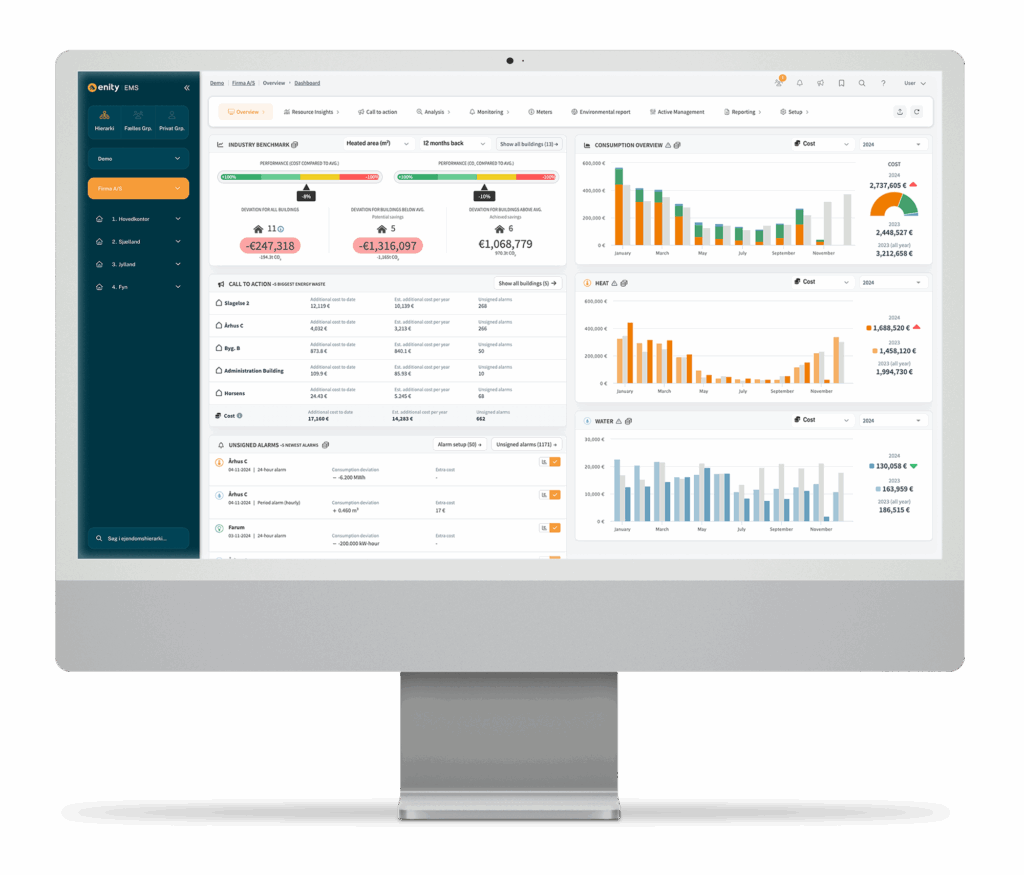

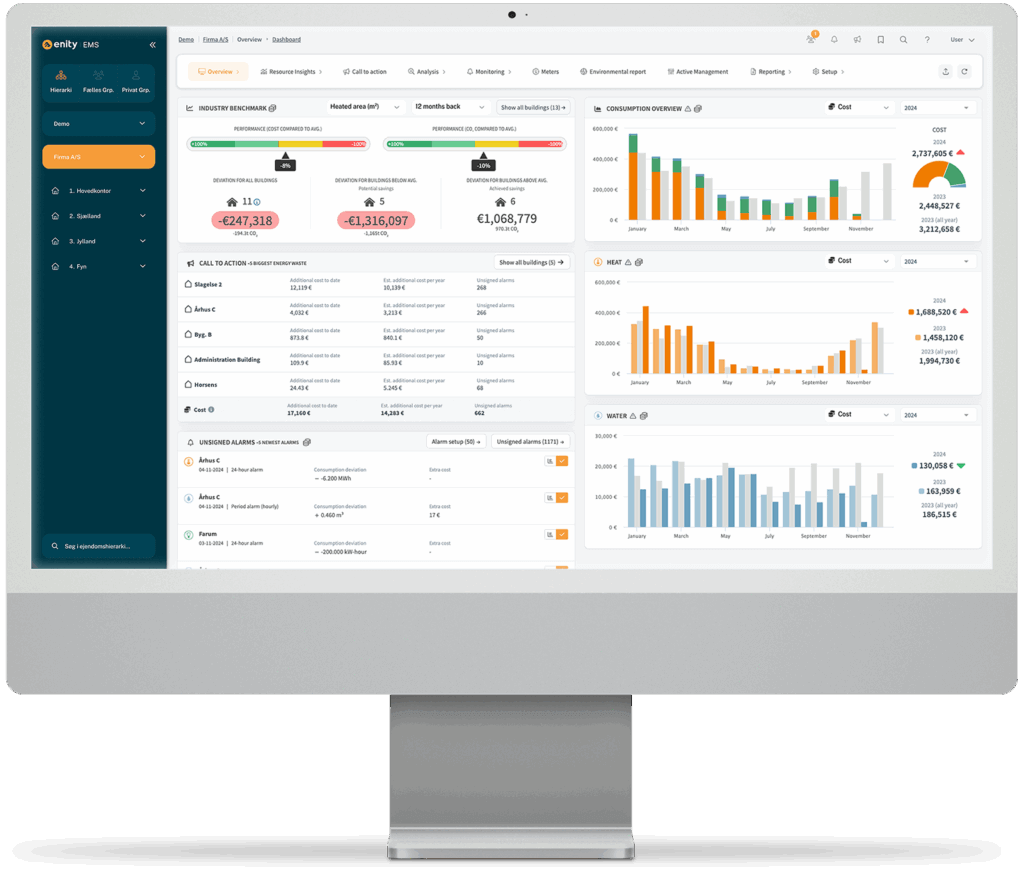

Gain visibility into energy consumption with an Energy Management System

In larger buildings, energy consumption is too complex to manage efficiently through manual checks or isolated measurements. Heating, ventilation and cooling systems interact, and operational changes can quickly have a major impact.

An Energy Management System (EMS) can collect energy data from BMS systems and meters into a single overview. This enables continuous monitoring and early detection of deviations before they develop into major energy losses.

An EMS can be used to:

- identify abnormal consumption at an early stage

- monitor the impact of operational adjustments

- create transparency across multiple buildings

For organisations managing multiple buildings, this ensures that issues such as unintended night-time operation or poor system interaction do not remain hidden throughout the winter.

Conclusion

Optimising energy consumption in winter operation is not just about turning the heating up or down. It is about system interaction, correct control settings and insight into how the building actually uses energy in daily operation.

By working systematically with heating, ventilation, BMS and energy data, buildings can significantly reduce energy consumption without compromising occupant comfort. Winter operation clearly highlights the difference between good and poor building management.

FAQ: Energy optimisation in winter operation

How can energy consumption be reduced in building winter operation?

By ensuring proper interaction between heating, ventilation and control systems. The greatest savings are often found in operation and regulation rather than in new installations.

What are the biggest energy consumers in buildings during winter?

High ventilation air volumes, incorrectly adjusted heating curves and systems operating outside occupied hours are among the largest contributors.

How does ventilation affect energy consumption in winter?

Ventilation leads to heat loss when warm air is exhausted. Over-ventilation therefore increases heating demand unnecessarily – even in systems with heat recovery.

What is a heating curve, and why is it important?

The heating curve controls the supply temperature of the heating system based on outdoor temperature. An incorrect heating curve can lead to overheating and unnecessary energy use.

How are faults in BMS operation detected?

Faults are typically identified through continuous monitoring of operating times, temperatures and energy consumption – especially outside normal working hours, where an EMS provides visibility and highlights deviations.

How can energy waste be identified in larger buildings?

By comparing energy consumption with actual operation and usage. Deviations over time are often indicators of faults or inefficient operation.

Enity EMS

One platform for all your consumption data

To make confident decisions about your energy consumption, you need insights that are presented clearly, concisely, and in one place. Our goal is to organise your data in a way that means trends are clearly recognised, problems easily spotted, and cost saving opportunities effortlessly identified.

- Dashboards – easy customisation, you decide what you see

- Tracking tools – alerts, budgets, and site comparisons

- Data exports – ready for ESG, CSRD, ISO and internal use

Download brochure

Read more about energy efficiency with Enity EMS. To the benefit of both the budget and the climate.

Book a demo

We show you the possibilities and potentials for optimizing your energy consumption.